info@rbbuilders.be +32 (0)2 256.92.36

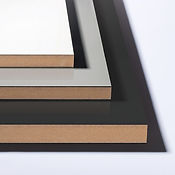

MDF, HDF

Vezelplaat met gemiddelde dichtheid (MDF) is een veelzijdige plaat op houtbasis met een goede bewerkbaarheid. MDF heeft een consistente structuur en dichtheid en een zeer glad oppervlak. Daardoor is het geschikt voor gefreesde, gelakte en geschilderde afwerkingen.

Bij de productie van MDF worden houtspaanders tot vezels vermalen en onder hitte en druk met kunsthars gebonden. MDF wordt vooral gebruikt voor de meubelindustrie, plinten, architraven, verpakkingsmateriaal, in de deurenindustrie en in alles van boekomslagen tot schoenen.

Vezelplaat met hoge dichtheid (HDF) bevat meer houtvezels per kubieke meter dan MDF-plaat. HDF wordt voornamelijk gebruikt als kernmateriaal voor laminaatvloeren.

High Density Fiberboard (HDF) is een gefabriceerde plaat die onder hoge druk en hitte wordt vervaardigd uit met hars gebonden houtvezels. HDF is een niet-dragend product voor binnengebruik in droge omstandigheden. Door zijn zeer fijne oppervlak is HDF geschikt voor verschillende coatings - fineren, lamineren, verven en lakken. Kronospan HDF is verkrijgbaar in verschillende diktes en met een geschuurd oppervlak aan één of beide zijden.

Norm

EN 316; EN 622-5

Emissieklasse

E1 (EN ISO 12460-5)

Kenmerken

- Goede mechanische prestaties

- Hoge stabiliteit

- Homogene eigenschappen

- Geringe zwelling in dikte

- Perfect voor schilderen lamineren, fineren en foliën

Toepassingen

- Meubelcomponenten

- Scheidingswanden

- Bekleding

- Raamwerk voor gestoffeerde meubelen

- Ontwerp van keukendeuren

- Verpakking

Norm

EN 316; EN 622-1

Emissieklasse

E1 (EN ISO 12460-5)

Kenmerken

- Gemakkelijke verwerking

- Hoge stabiliteit

- Verhoogde dichtheid

- Glad oppervlak

- Geschikt voor oppervlaktetoepassingen (melamine-bekleding, folie, fineer, enz.)

- Onafgewerkt

Toepassingen

- Interieur

- Meubelcomponenten

- Achterkanten van kasten

- Deuren, scheidingswanden